Perfect Info About How To Check Crankshaft End Play

There are several methods utilized in the process of setting end play.

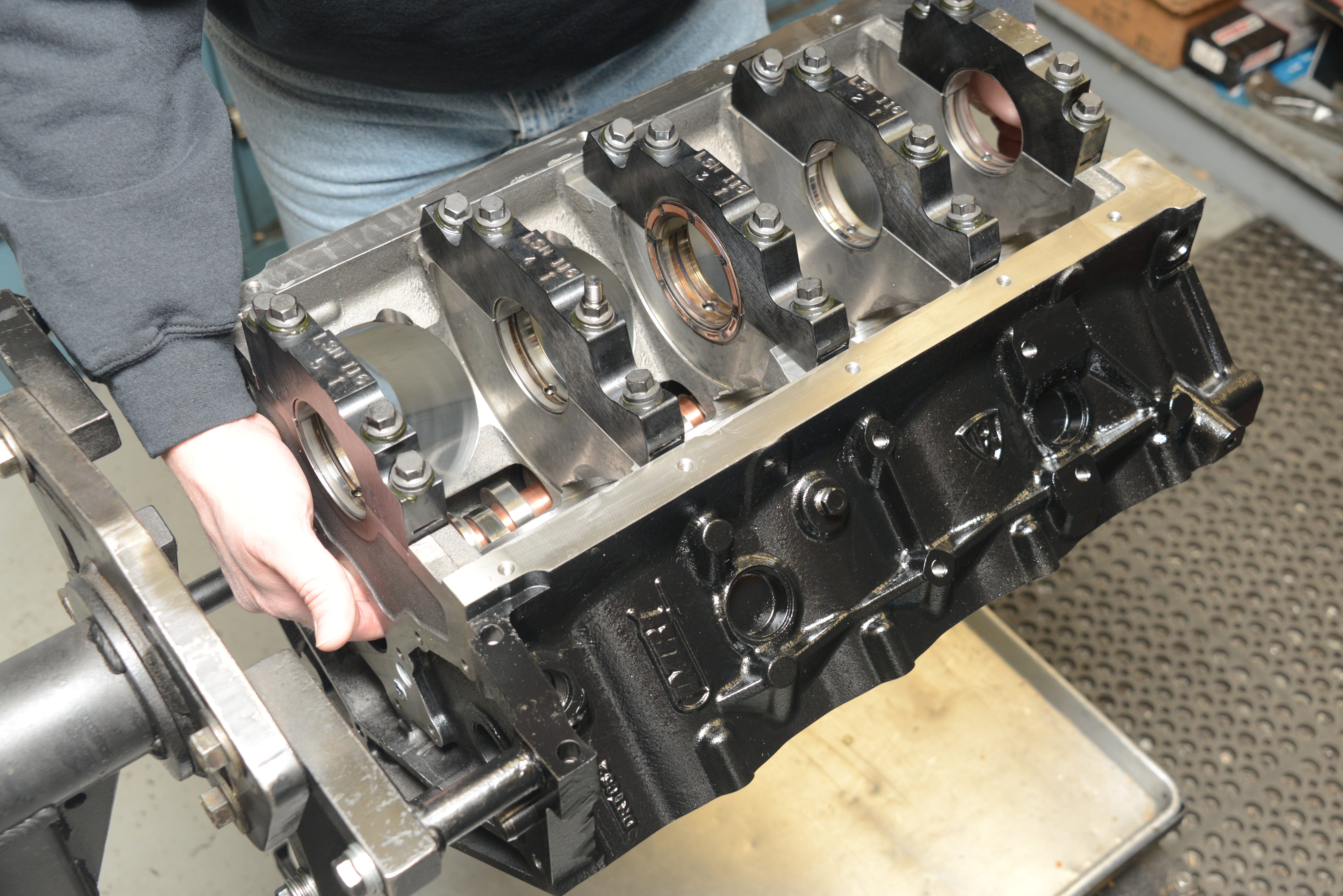

How to check crankshaft end play. Crankshaft end play refers to the axial movement or displacement of the crankshaft within the engine block. On a newly assembled engine, before tightening down. Transmissions can create a tremendous amount of forward force on crankshafts, especially in high performance applications.

I want to check my car for crank walk and i. I did pry the crankshaft front and back and it does move about. Excessive end play can lead to.

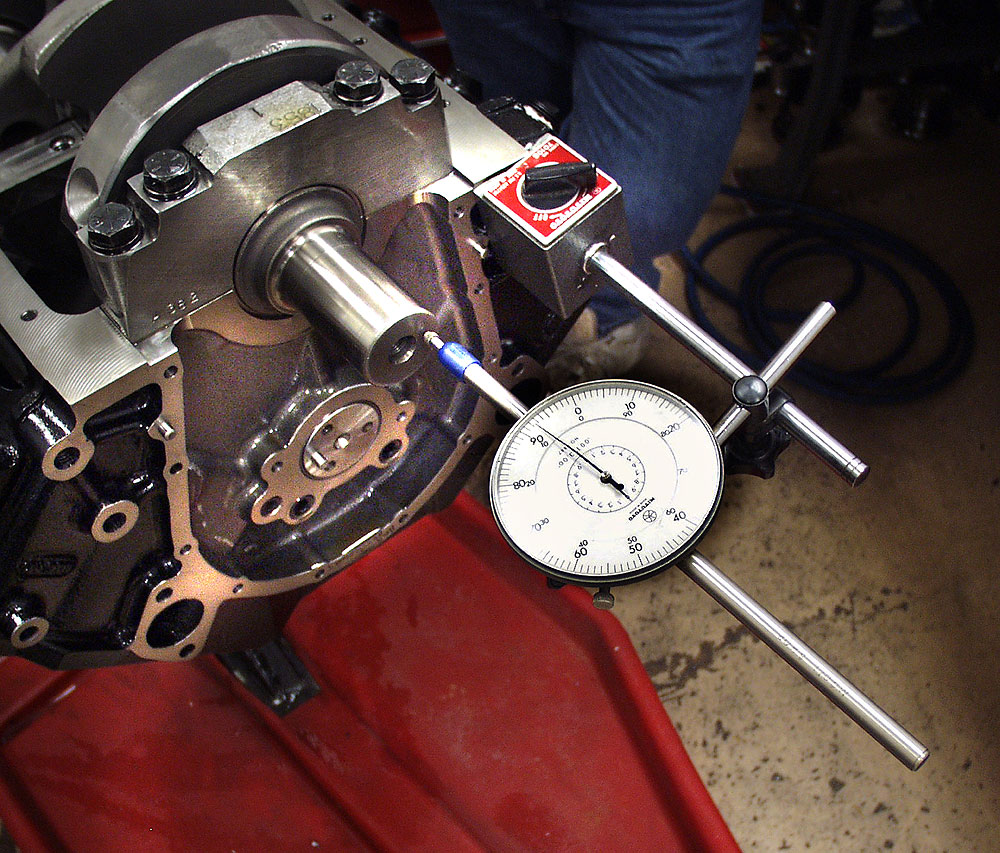

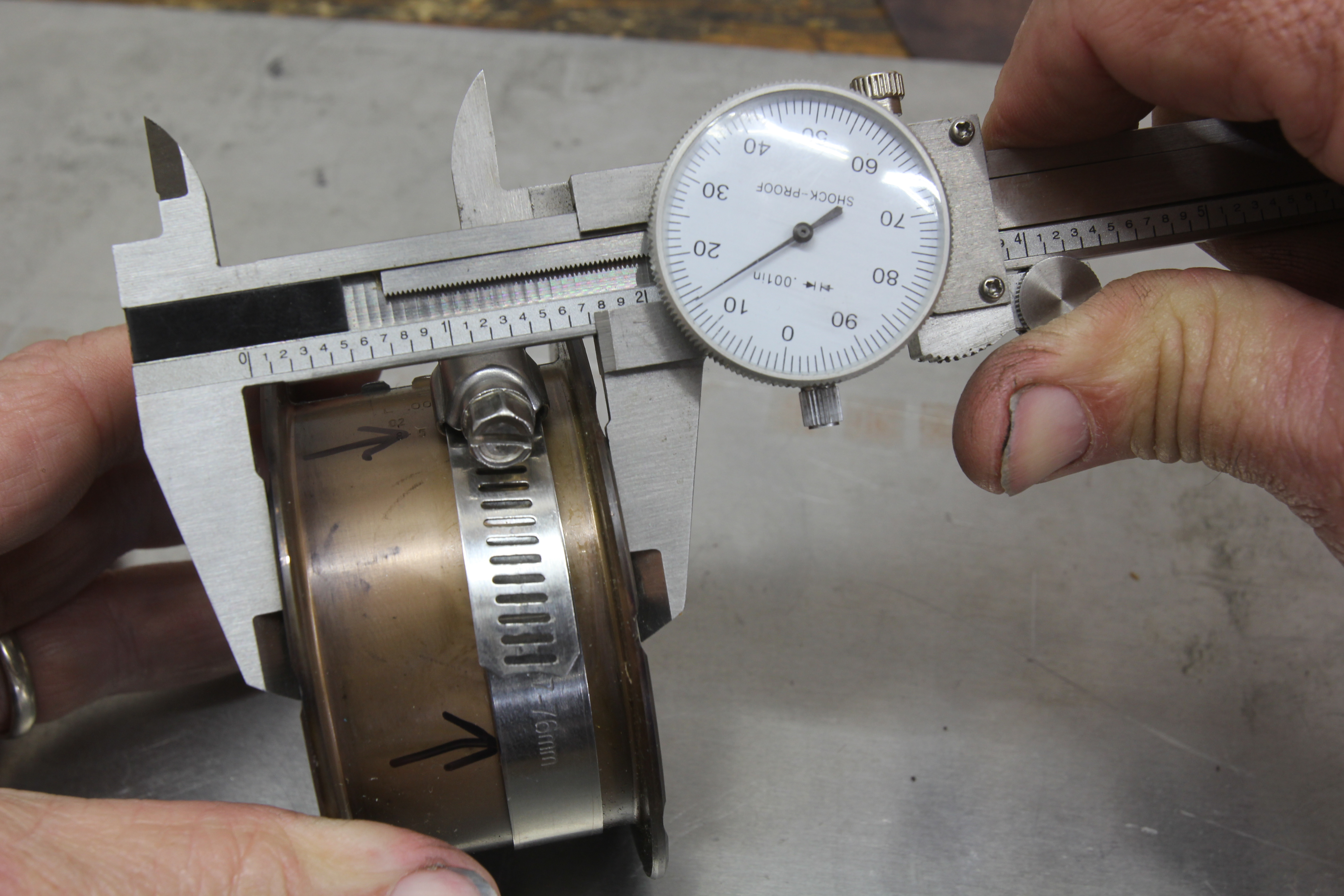

Be sure to torque down all nuts and bolts (including the cases) to the proper specs. Which instrument is used to check the end play of crankshaft? One method is to machine the thrust bearing and cavity to a very accurate value so that the end play is.

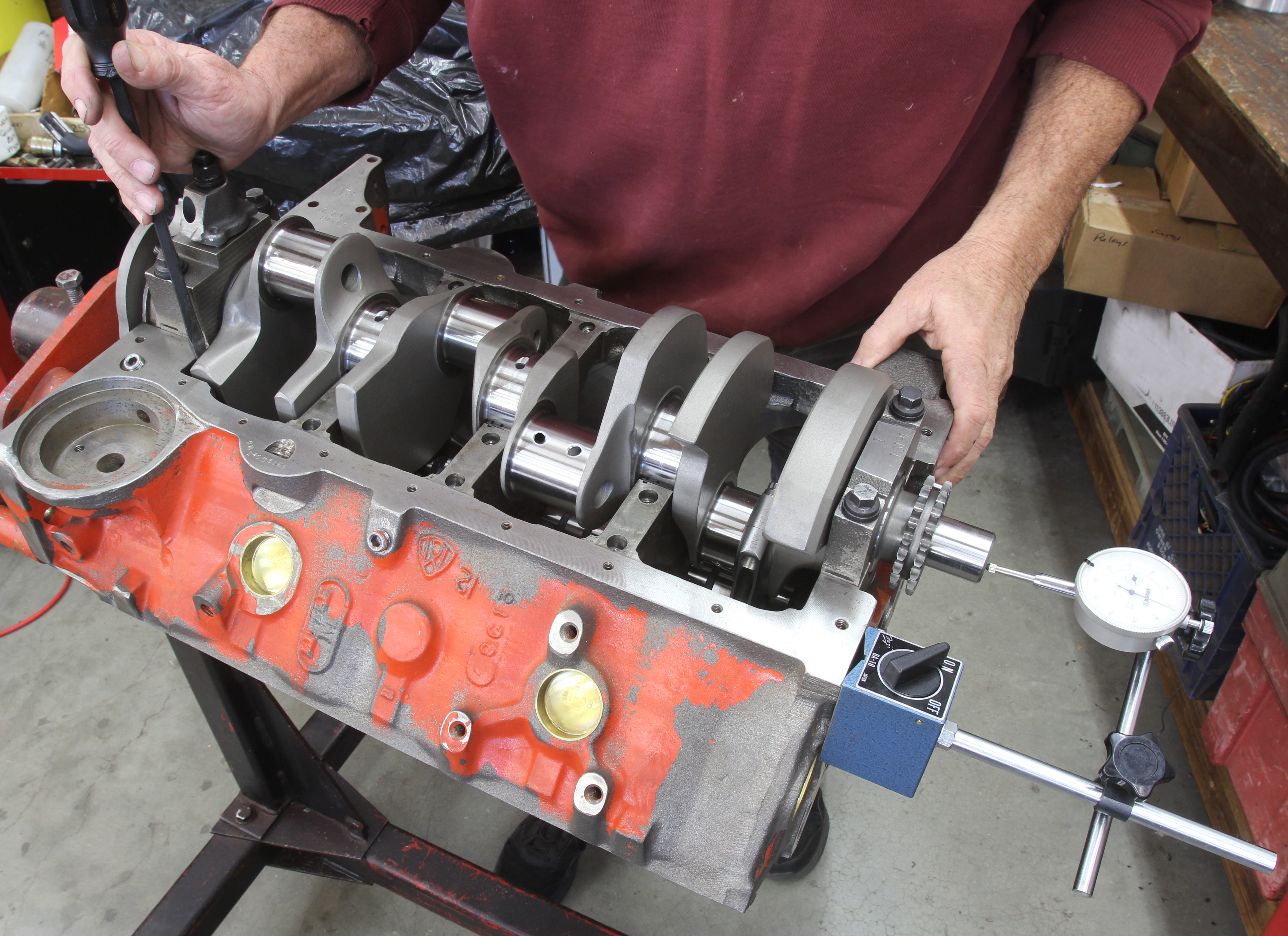

#1 1fast2g 20+ year contributor 138 0 sep 19, 2002 la puente, california how do you check crankshaft end play? Calculate end play: Measuring the crankshaft end play, will help you estimate if your engine needs a total overhaul.

When you check end play. This is important when performing an engine overhaul/rebuild because depending on a certain vehicle. Want to learn more about performance engine building?

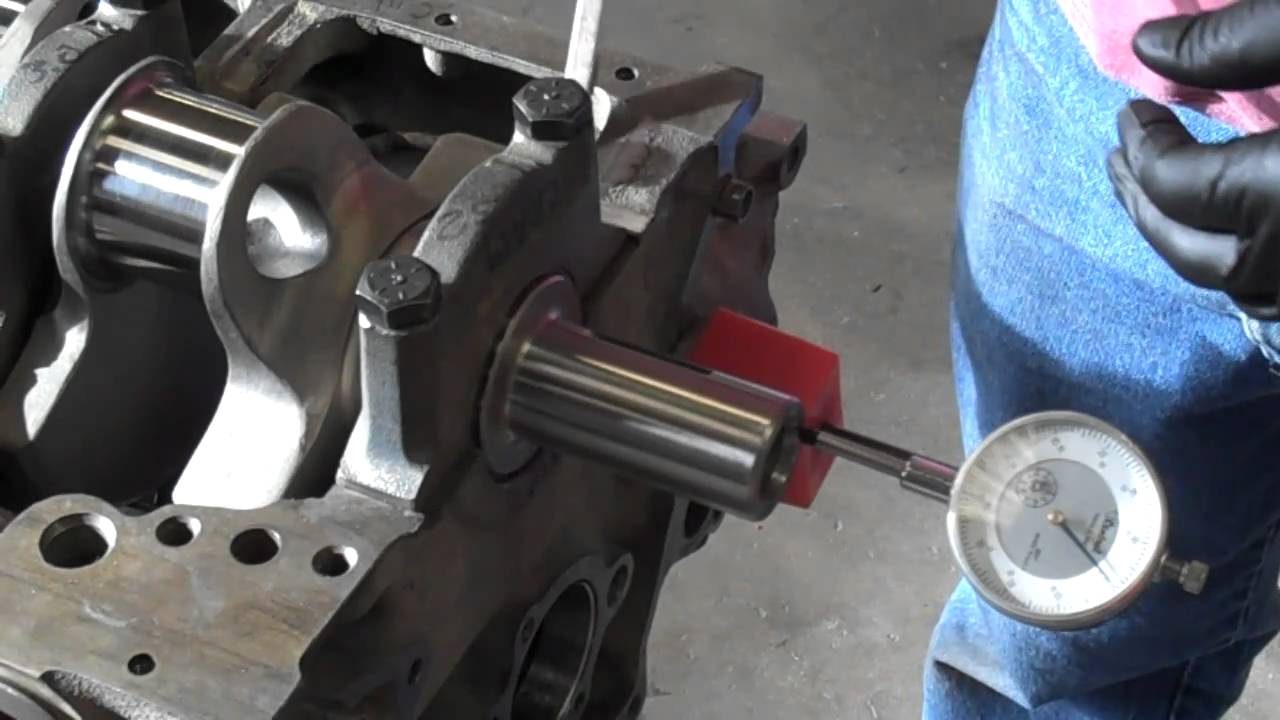

We show you how to do the job in this tech segment. To measure end play movement: First, i can’t find the original tsb that gives the end play spec that you measure with the gauge.

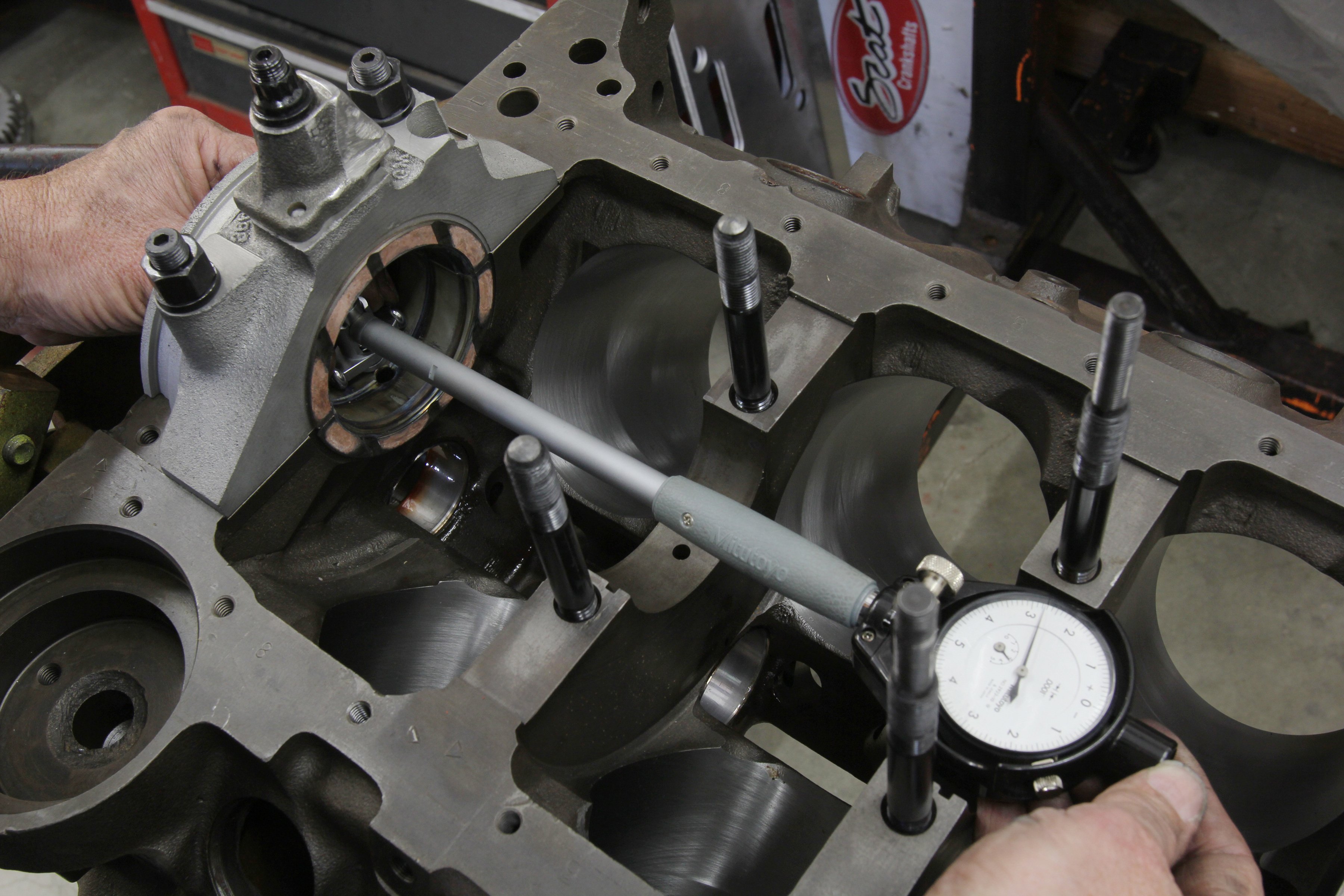

How check your crank shaft end play and how to adjust if you have too little or too much (thrust bearing adjustment)feeler blade methodsbc spec is.003 to.0. The best way to check endplay is with a dial indicator installed with its plunger parallel to the crankshaft axis. I do this with a dial indicator on my all.

Crankshaft “end play” is measured as the clearance between the crankcase thrust washer and the axial mating surface of the crankshaft (see figure 1). It is essential to have a certain amount of end play. To calculate the crankshaft end play, subtract the minimum reading from the maximum reading obtained from the dial indicator.

That's why it's important to check crankshaft thrust. Clean the engine case around one of the top bolt holes used to connect the engines to the transaxle. If the result of the measurement is greater than or equal to 0.15 millimeters,.

This provides for a clean flat surface. In this video i share with you how i check the crankshaft end play clearance, also known as thrust clearance.