What Everybody Ought To Know About How To Treat Steel

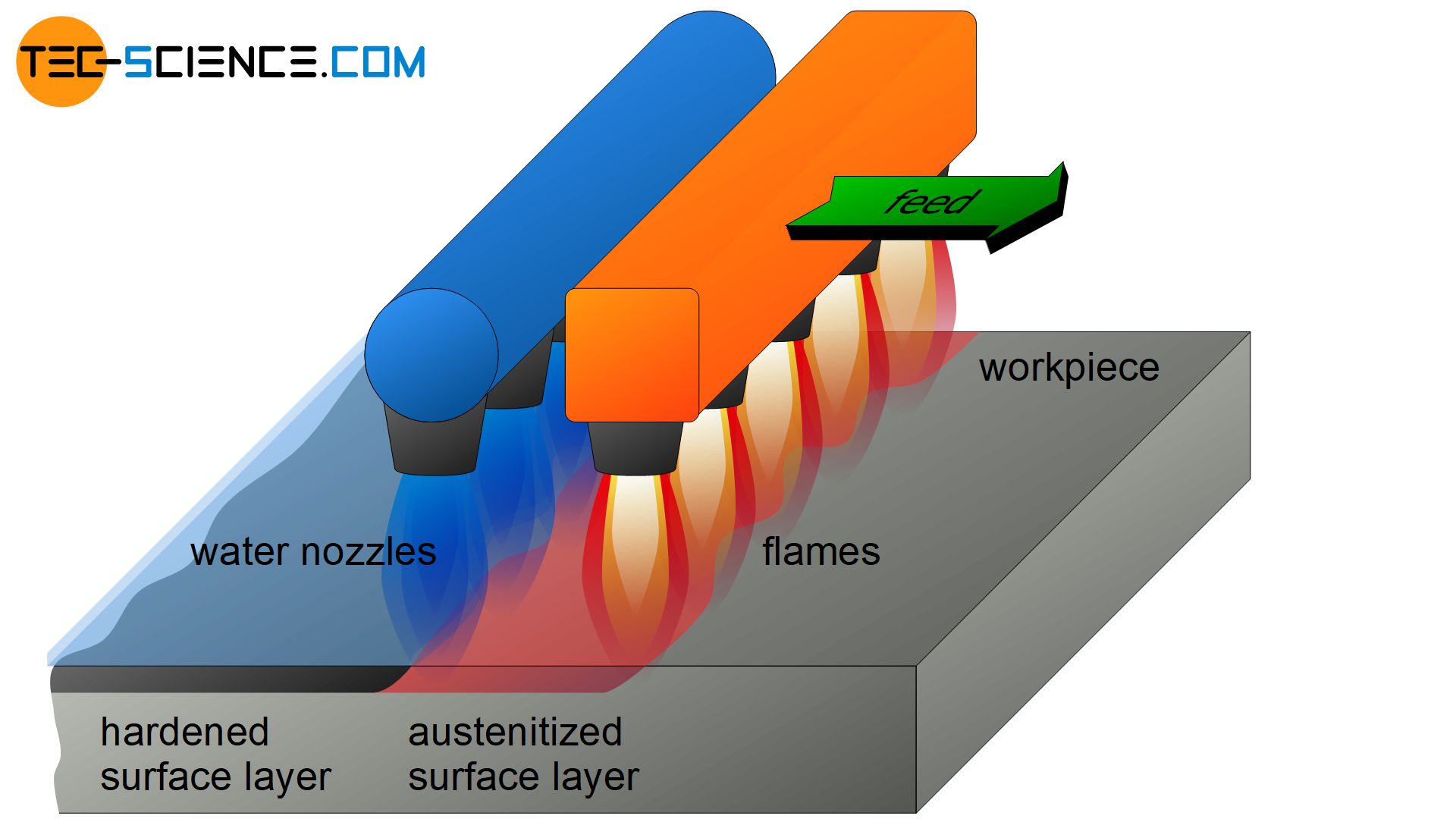

Preheating helps reduce thermal stress when the metal is exposed to higher temperatures later in the.

How to treat steel. Invest in an accurate thermocouple or pyrometer. It will also have a specific method. Stainless steel should be heated and cooled in a controlled.

Oleksandr's prosthetic eye twinkles, damaged from the siege of the azovstal steel plant in mariupol, one of the more savage battles of the invasion’s first three. This is all the stuff your going to need. With consideration and care, you can heat treat d2 tool steel to create a good balance of hardness and toughness.

That also makes it great for knives. Use appropriate heating and cooling methods. S7 material hardening and tempering.

This formula has a melting point temperature of 560 ℃ and a service temperature of 580 to 620 ℃. Photocatalytic degradation is a promising way to treat emerging pollutants in wastewater. The steel used to make springs needs to be tough, resilient material.

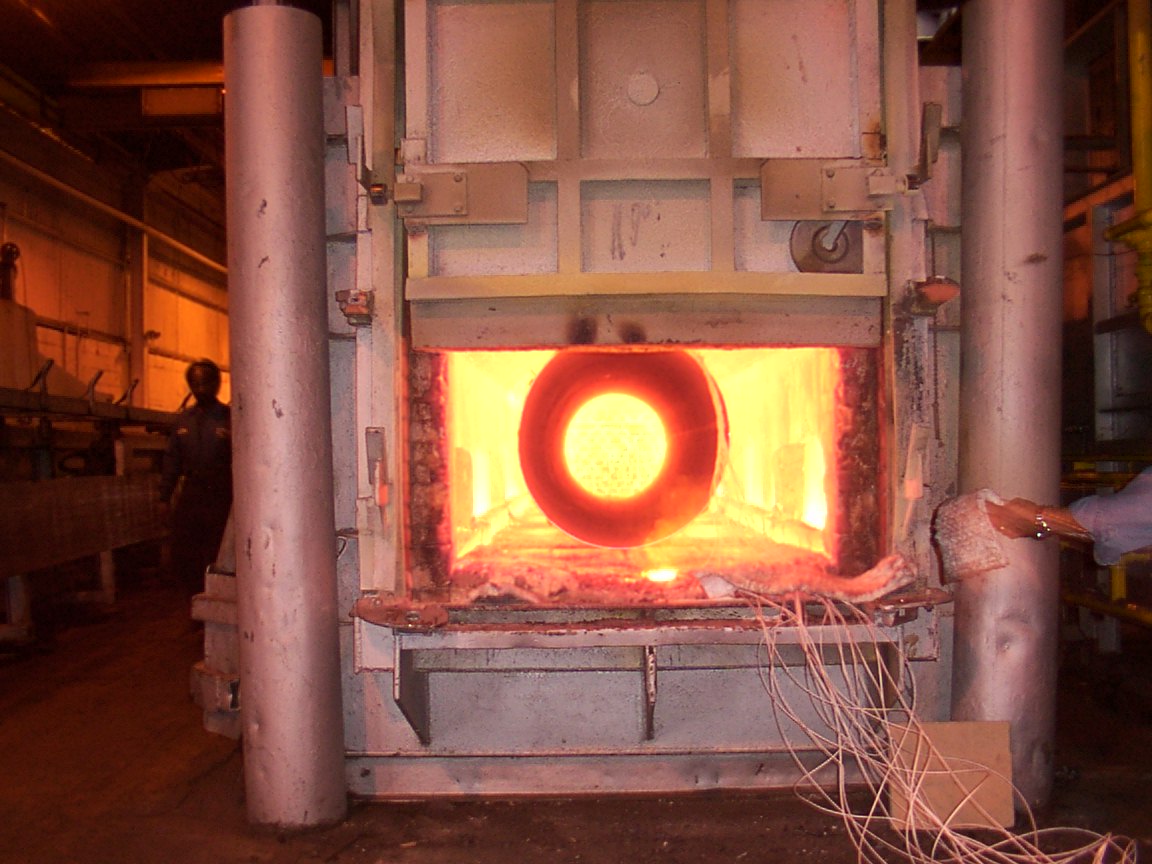

Buy a small oven with. Put the blanks in an oven for 2 hours at 200 degrees celsius. Heat in furnace to 1650°f and hold for six hours.

The following are key steps for each process. For tools or hss steel parts with effective sizes less than. Or, for smaller parts, you can save a bit of time by cycling the.

Most commonly used with aluminum, copper, steel, and brass, this process softens the metal to make it more workable by enhancing machinability, ductility, and. In particular, steel alloys are heat treated routinely to. Penetrol is an additive for oil paint it's supposed to remove brush marks and increase the working time of the paint.